Technology

CNC Transfer Machines

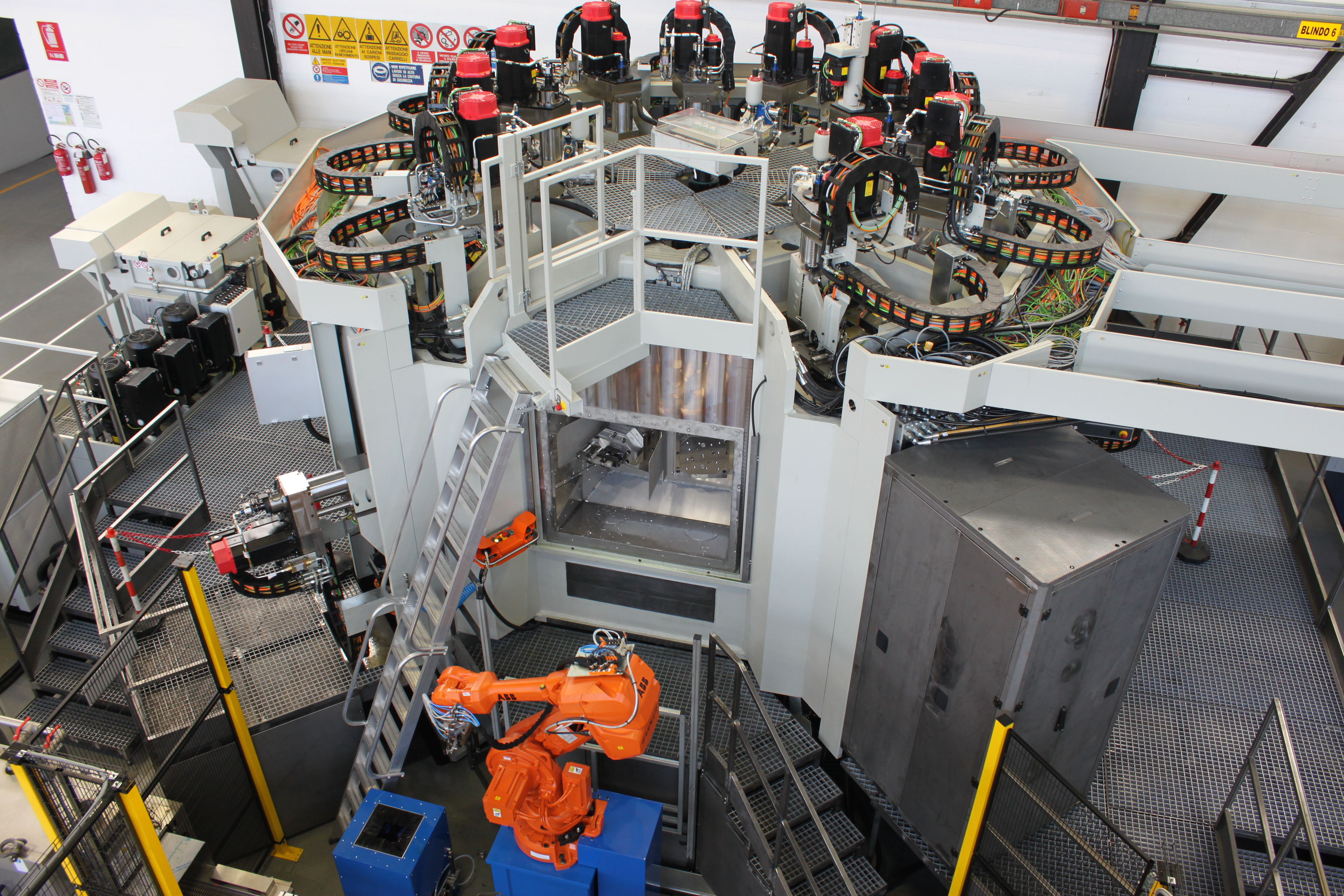

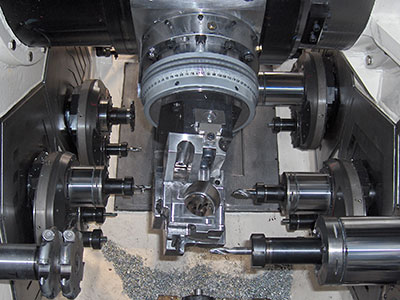

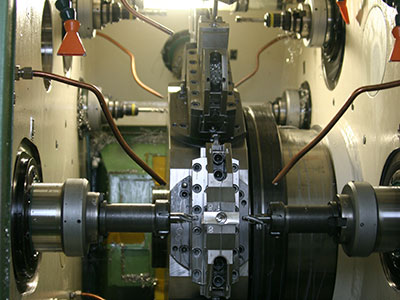

Our CNC Rotary Transfer Machines utilize multiple workstations in both horizontal and vertical axis performing various operations simultaneously. With 4 axis machining, multi tool changers for each spindle and 360° full rotational self centering chucks, JEBCO Manufacturing has the fastest most flexible transfer machine in the world. We will supply your aluminum forged, cast, or extruded products to the tightest tolerances, competitively. Today’s Transfer Machines will outperform conventional CNC machining centres by up to 10 times standard rates making the product they produce globally competitive. Our Rotary Transfer Machine’s repeatability is remarkable, mainly because we can machine most parts in 1 chucking with complete 4 axis machining. Our Transfer Machine’s flexibility doesn’t stop there. With dual chip evacuation, visual robotic loading for repeatability as well as pit-stop set-up system, we have the ability to deliver your products quickly when you need them. JEBCO Manufacturing is committed to your needs and we will ensure they are met every time.